Joinery 4.0 - consistency from design to CAM to MES. Smart Factory offers various software modules for the HOLZ-HER nesting machining centers pre-installed on a single central master computer. All relevant processing data can be transferred directly to the nesting CNC machine via a standardized CSV interface - for perfect processing results.

Campus V7 Plus software suite with BetterSim material removal simulation

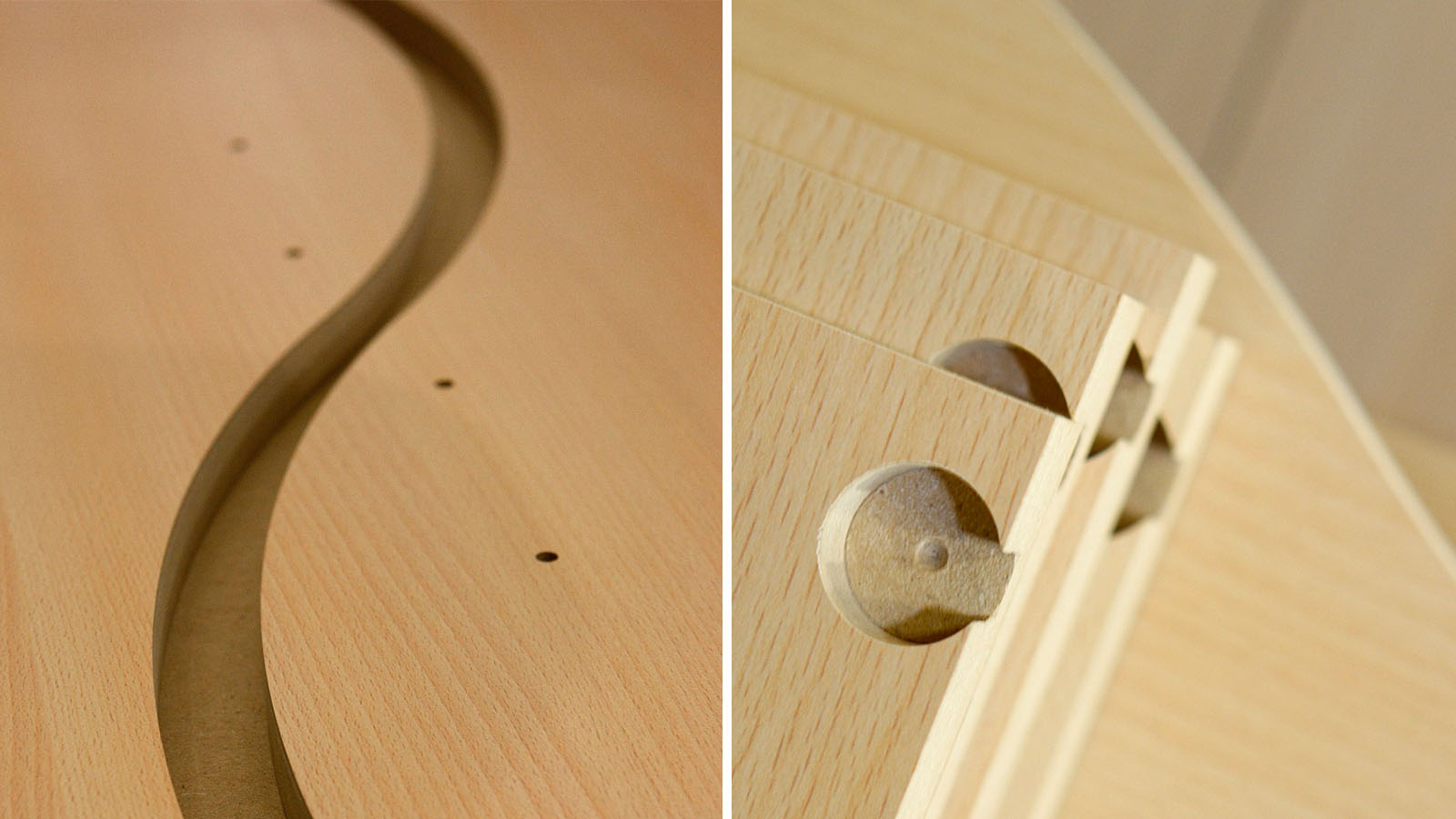

The Campus V7 package is a well-rounded solution for all-rounders and specialists with high demands on software automation. The 4solid option also enables 3D CNC machining of surface models in two variants. The BetterNest nesting software has also undergone some changes. For example, the new Common-Line-Nesting function enables time-saving and precise formatting and drilling of right-angled furniture components on the nesting CNC machines.

CAMPUS V7 BetterNest Nesting Software

HOLZ-HER offers the "BetterNest" software as an add-on module to the CAMPUS / NC Hops software for the functional nesting machining centers of the DYNESTIC series.

The module is available as pure rectangular nesting or as a free-form variant and offers previously unattainable nesting results with significantly less waste than conventional nesting software.

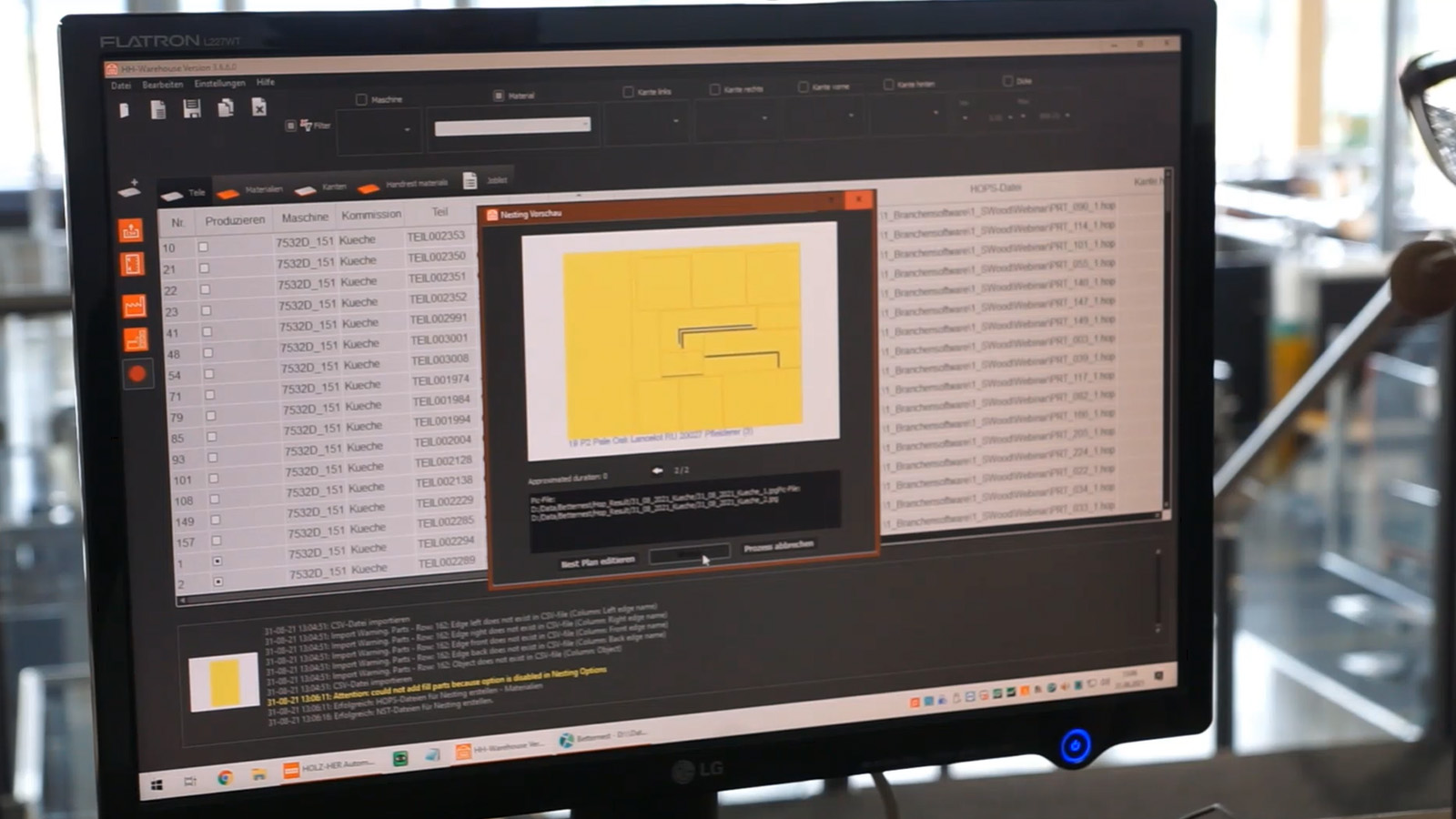

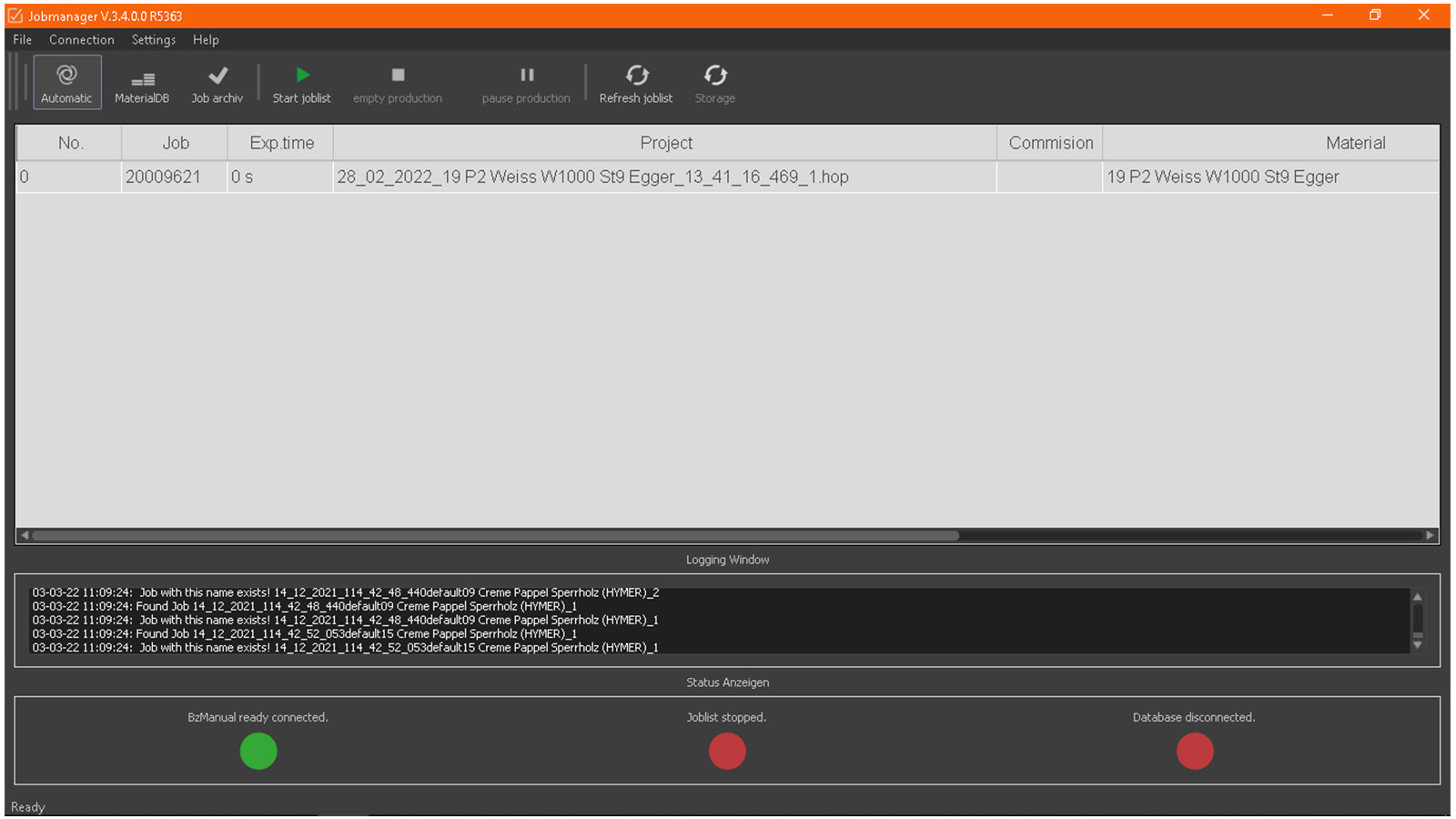

Warehouse

In the overall Smart Factory system developed by HOLZ-HER, Warehouse has the task of actively processing the complete parts inventory that is to be transferred to production and transferring it to the subsequent production processes. Using Warehouse, it is possible to import parts from any CAD/CAM system or even from an ERP system via predefined interfaces or using freely definable import filters.

Optimization of the production flow

Work preparation

- Collection and output of HOPS files | External CAD/CAM system

Warehouse

- Import of .HOP & .CSV possible | Sorting by material, commission, priority and machine | The components to be produced can be distributed.

Optimization & production

- CNC: Bed nesting

- DBS: HHOS

- STORE-MASTER: StoreIn-Tool